Nathaniel Peek started Spin Cycle Clothing four years ago in Adelaide, South Australia, to supply custom-made racing kit to serious cyclists, but he knew that if he wanted to grow the business he needed a point of difference.

He then combined his love of cycling – the 39-year-old has competed in all disciplines from road to mountain biking – with a decades-long career in design and technology to develop a laser scanning system that tailors each piece of clothing to the rider.

“More than 50 per cent of brands are made at the same factories in China from the same patterns,” said Peek.

“My system, which also knows the limits of the fabric, how much and which way it can stretch, is a massive point of difference.”

Peek discovered a medical scanning system in his previous job at Microsoft and developed a software interface that translates its laser-precise measurements into manufacturing-ready CAD patterns.

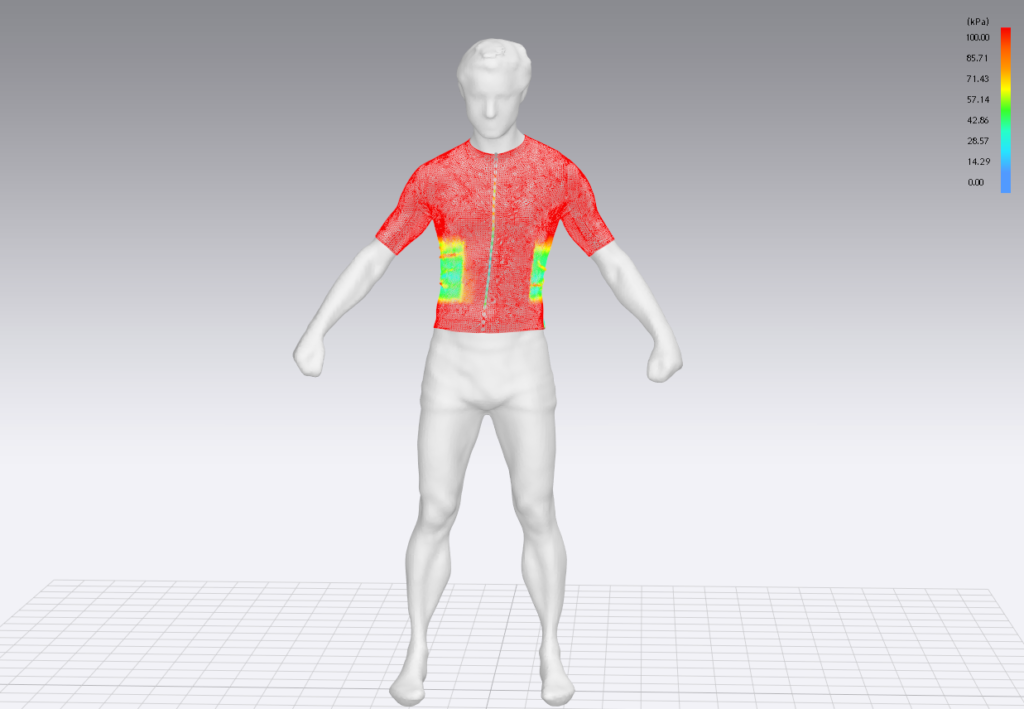

Customers stand on a rotating platform as a laser scans their body to make a 3D image, which is then used like a dressmaker’s doll to virtually tailor the clothing.

Peek’s software takes account of the properties of the fabric – he uses high-end fabric from Schoeller – and the operator simply adjusts the levels until the display indicates the perfect fit by turning red. Once fitted, Peek’s software converts the measurements into CAD pattern files based on the international Gerber tailoring standard and sends them to a manufacturer in China.

“It takes less than two minutes to get a complete kit,” said Peek.

Virtual clothing is draped on the 3D model and adjusted until the optimal fit is achieved, indicated by the pattern turning red. Photo: Spin Cycle

Peek said he develops the finished product around what the customer would use it for.

“For riders in Tasmania, for example, I know they will be cold and wet so we use the right fabric to keep them at the right temperature,” he said.

All the clothing is also rated at SPF 30+ for sun protection, with his all weather jacket selling for AUD$270.

The entire laser system, which at the moment costs $20,000, will be ready to roll out by August.

Peek is looking to the large European and American cycling markets and to expand into the global market for sports and fitness clothing, which according Global Industry Analysts will reach US$231.7 billion by 2024.

He is seeking $500,000 in funding to help get sports and health businesses to buy into his system as a unique offering to their clients.

“That [the funding] will allow us to go full time on the project,” said Peek, who funds the business through freelance tech jobs and selling his Spin Cycle range.

He has also teamed up with Associate Professor Richard Kelso, who helped design an aerodynamic helmet for Scott Sports, to test his clothing in the at the University of Adelaide’s wind tunnel so he can develop fast skinsuits for high performance teams.

Peek said he started with cycling apparel because it is what he knows but his system could be used to tailor any type of clothing, such as wedding dresses.

“There are multiple revenue streams and we can roll out for the whole apparel industry,” he said.

Image: Nathaniel Peek testing his custom skinsuit in the University of Adelaide wind tunnel in South Australia.

Trending

Daily startup news and insights, delivered to your inbox.